LET US MANUFACTURE FOR YOU!

WINCO Generators is a leading manufacturer of generators, originally founded in 1927. Throughout the years, we have grown and adapted to meet many unique customer needs. Since 1977, we have been manufacturing in our factory sprawling on 17.5 acres in Le Center, Minnesota. Today, we want to partner with you to help produce your custom products and components.

We offer machining, metal fabrication, painting, wiring, and assembly services. WINCO is committed to exceeding customer expectations and creating quality solutions per your precise specifications, quality standards, and on-time delivery deadlines.

With the amazing Manufacturing and Engineering Team on-site, we are well equipped to serve a diverse customer base in a variety of industries that include:

– agriculture

– manufacturing

– construction

– many more.

Contact a WINCO Account Manager by phone or email to get your project started.

POWER IN QUALITY

Our ability to engineer, design, machine, fabricate, and assemble our units under one roof allows us to maintain a higher standard in quality. Our campus spans 17.5 acres and is dedicated to producing high-quality machines and components.

CHEMICAL WELDING CELL

- 3 Miller Mig Welding Booths

- 25′ travel capacity

- 5′ x 10′, 4′ x 10′, 4′ x 4′ Lazy Susan welding tables

- ACME Spot Welder

- 24″ throat

WASH & PAINT

- 100 sq ft High Pressure Phosphate Wash and Rinse Bay

- 80 Cubic Feet Phosphate Carousel Washing Machine

- 2 – 7′ x 16′ Powder Coating Booths

- 3 – 400 degree 17′ x 7′ Curing Ovens

- Controlled Pyrolysis 800,000 BTU Burn Off Oven

FIBER LASER

- Mazak Optilex Nexus 3015 4kW

- 5′ x 10′ automated pallet changer

- Onsite liquid nitrogen

- Cuts 22ga steel up to 1/4″ plate

CNC MILL

- Okuma Genos M560-V

- 32-tool magazine

TURRET PRESS

- Weidemann Magnum 5000

- 52-tool capacity

- Sheer up to 1/4″

BRAKE PRESSES

- 40T 4′ brake press

- 60T 8′ brake press

- 135T 10′ brake press

- 175T 12′ brake press

WIRE CUTTER

- Artos Wire Processor

- Fed by 48 spool wire carousel

- 20 to 2 gauge

- Dual ID printing heads

- 6-wire terminal crimping up to 4/0 wire

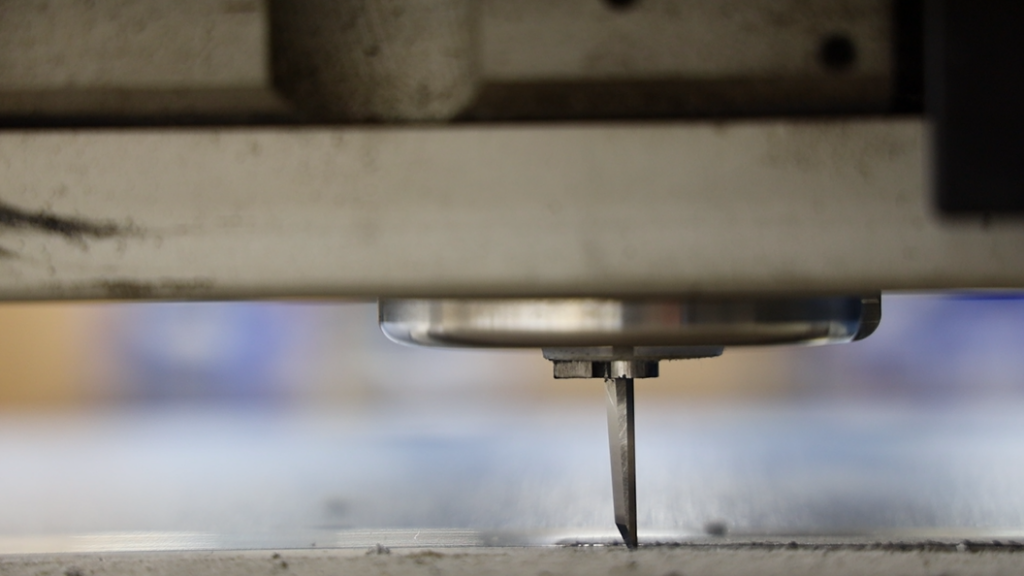

FLASH CUTTER

- 4′ x 8′ vacuum table

- Cuts 1″ sound barrier

- Cuts 1/2″ heat barrier

- Cuts 1/8″ solid rubber sheets

BAND SAWS

- Horizontal with 20′ capacity

- Vertical with 15′ throat

TUBE BENDER

- 1″ and 1 1/4″ diameter, up to 20′

LOAD BANK TESTING

- Simplex Titan 700

- 700kW 1ph – 3ph

- Simplex Infinity

- 110kW 1-ph

- Simplex Neptune

- 50.5kW 120, 240 1-ph and 480 3-ph

- 2 – Simplex Swift-E

- 1-ph x 10kW

Download and print this information by clicking here.